CIMC 40cbm Cement Tanker Trailer will be sent to Burundi

The Burundi customer from a construction company. He has been following the cimc brand for several years. For this time, the customer purchased the cement tanker trailer mainly for short-distance transportation of powdery substances, cement, etc. This customer first sent an inquiry through our website, and then the salesman slightly modified the drawing according to the customer's request. The factory finished quickly, and we sent some photos of the cement tanker trailer to the customer, he was also very satisfied. All the cement tanker trailers can be costomized to meet your requirement, All the CIMC cement tanker trailer will go through the pressure test and metal inspection testing, to ensure a good sealing property of our cement tank trailer. The customer also said that we can keep in touch frequently and there will be an opportunity to cooperate again in the future.

The main applications of this tank trailer include transporting cement, flour, lime powder, mineral powder, fly ash, chemical powders, and stone powder.

This type of trailer is widely used on large construction sites and cement factories and warehouses. The tank trailer uses compressed air to discharge powder from the tank.

Cement tanker trailers come in three different structures that include the horizontal, funnel, and lifting structures. Each structure is ideal for a specific type and weight of powder cargo.

Let us now look at the advantages and disadvantages of the three types of structure.

For the pneumatic trailer tank to work effectively, several safety considerations have been put in place. Basically, pneumatic tankers tend to have certain safety issues that need the attention of well-trained and competent drivers. Here are the two main areas that have to do with the safety of this type of tank:

Compressed air in the pneumatic system tends to move the cargo via pipes and compartments. For this reason, there should be accurate mechanical understanding and procedures of operation to ensure a smooth offloading process. The tank should also be kept in good condition through regular maintenance. Ideally, the only risks relate to the tanker itself and the cargo as a result of the breakages and blockages. Should there be air pressure leaks, injuries may result. Therefore, it is important to exercise caution at all times.

Operating the contemporary pneumatic tankers can now be conducted at a ground level. This largely reduces the risks of falling. In the unlikely event that the driver will be forced to climb onto the tanker, there are handrails and ladders securely fixed to reduce any chances of injuries.

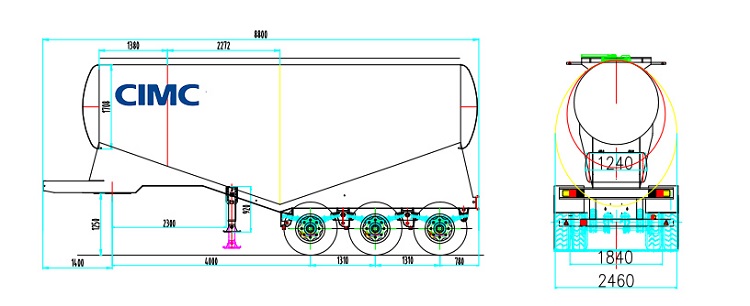

Details of the Cement Trailer

Based on orientation and structure, there are different types cement tank trailers as discussed below. Here are some of the many that you will find out there:-

The Horizontal Type

The terrain on which you are conducting your operations can also dictate the type of tank to buy or rent. On a steep slope, you need a tank trailer with the greatest stability.

You may not have issues with space but could be the payload is quite heavy transported along a steep gradient. The stability with this kind of cement tank makes sure that you engage in safe operations both during loading, transportation and offloading. There won’t be worries of spills or a tip-over. Still, with an increased stability, your insurance premiums will be kept low. This makes your operations very efficient financially and work-wise.

Drawing of the Cement Tanker Trailer

Advantages:

The design of this tank trailers allows it to transport a wider range of materials than a horizontal tank. The shipment can be either powder and granule material or the massive materials.

The pneumatic discharge can be used for powder and granule materials. The massive materials, on the other hand, are discharged into the designated pit by way of tipping gravity.

The angle between the cone bus bar and the horizontal plane is greater than or equal to 45°. Hence, this guarantees that the powder will slide to the bottom of the fluidized bed smooth.

The fluidized bed area in this type of tank trailer is not large. Consequently, the residual rate is very low.

The tank design and material reduce the left over material after discharge. The material also reduced the deterioration and pollution associated with powder shipment.

The funnel type of powder tank trailer is a good choice to transport food materials such as flour and powder chemical material.