Chapter one: What is triaxle with boards?

Chapter two: Why CIMC side wall trailer is more popular?

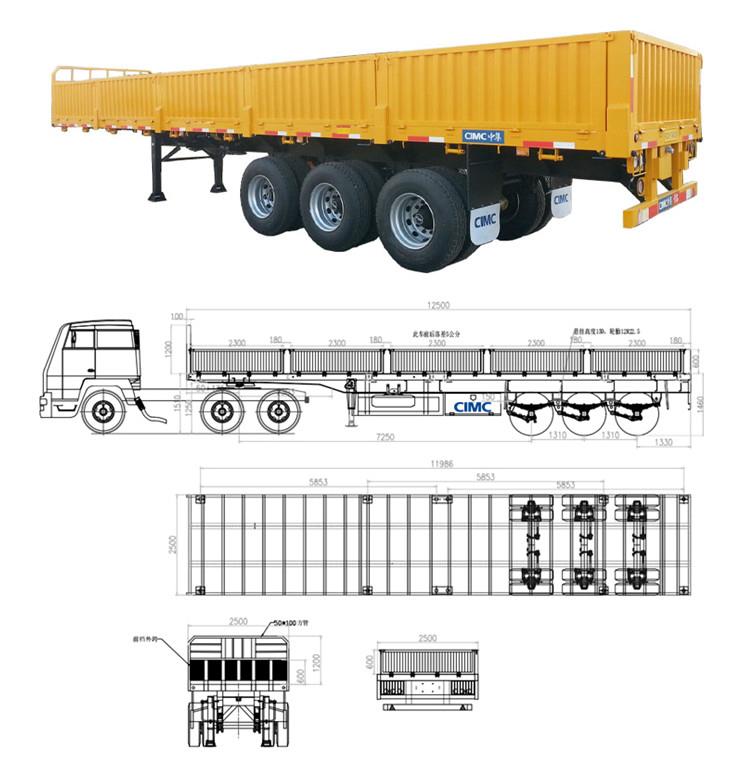

Chapter three: CIMC side wall trailer dimension

Chapter four: Production process of drop side trailer

Triaxle with boards is your ideal partner for multipurpose solution catering to vast range of applications including Cement Bags, Agri bags, Tiles, Jumbo bags, steel coils, etc.

Its higher payload carrying capacity, better mileage and availability of different product variants catering to varying customer's needs. The vehicle provides you with longer tyre life, high fuel efficiency and less maintenance cost which gives you higher revenue and lower operating cost, substantially increasing your overall profit.

With ability to carry heavy loads with utmost ease and OEM assured body warranty, CIMC triaxle trailer with board is an ideal choice for your business.

Advantages:

Can be utilized for multiple applications

High Strength Light Weight 1-2% more payload

More payload gives more revenue generation capacity

High strength steel, submerged arc welding and 2 coat paint Longer Life

Best in class axle and braking system provides better tyre life

Optional ABS for additional safety

CIMC side wall trailer has a longer service life than others. CIMC side wall semi trailer adopts advanced intelligent manufacturing equipment such as finite element analysis, modular design, laser cutting machine, robot welding, etc., from the design source to the product processing and manufacturing, the entire process is strictly required to ensure that every side wall trailer delivered to the customer. They are all high-quality and qualified products.

The specific advantages are as follows:

1. The bracket adopts a high-strength material upper end closed design structure, which can meet the direct connection of the lower wing plate of a side wall trailer for container or cargo.

2. The triaxle with borads trailer adopts a new type of suspension system with high strength and strong impact resistance, which has a long life and is more reliable in durability..

3. The guide arm can choose double leaf spring and single leaf spring. The optimized single-leaf guide arm structure, lightweight design, three bridges reduce the weight of more than 200 kg, and has good guidance and super reliability and stability.

4. The guide arm bushing is made of inner and outer steel, and the middle vulcanized rubber design structure has stronger load resistance and more stable vehicles.

5. Reduce tire wear and fuel consumption. Under the same road conditions and load capacity, fuel consumption per 100 kilometers can be reduced by more than 1.2 liters.

6. Imported brake pads and implanted wear alarm device. Effectively guarantee the braking performance of the bulk cargo semi trailer during operation.

7. Brake discs containing alloy elements, anti-cracking, anti-wear and high temperature resistance. Super long warranty of 200,000 kilometers, maintenance-free, brake life up to 10 years and 1.5 million kilometers.

8. The use of low temperature resistant brake air pipe makes driving safer. The side wall trailer wiring harness uses 7-core wiring harness, without any grounding treatment, the lamp can work normally, the use failure rate is low, and it does not need to be replaced for life.

Details of CIMC Triaxle With Boards

CIMC most popular triaxle trailer with boards specification:

L*W: 12500mm*2500mm

Sidewall Height: 1000mm

Max. Payload: <60T

Application: Coal/Cargo/Containers Loading

Material: Q345B Steel

Bottom Platform: 3mm-thick checkered plate

King Pin: JOST brand 2.0 or 3.5inch(bolted or welded type)

Support leg: JOST brand

Suspension: Airbag / Mechanical / bogie suspension

Axles: 3 axles, FUWA/BPW/CIMC/other

Tires: 12 units, 12.00R22.5/315 80R22.5(Specially designed and for oversea markets)

Brake System: WABCO

Electrical System: 24-volt lighting system

1. Stage of cutting steel sheet material

According to the drawings of each part produced by the design department, each part is cut out with a CNC cutting machine, such as beam webs, reinforcement plates, standard small accessories and so on.

2. Submerged arc welding beams, beams fixed

The second step is to fix the cut web and the upper and lower wing plates to weld points, and then weld the beam by submerged arc welding.

This step is very important. Both the fixing of the beam and the submerged arc welding are very demanding. If the technical process is not feasible, the beam will have problems. Can the drop side trailer be okay if something goes wrong?

3. Opening, calibration beam, through beam

First cut out the web of the beam to cut out U-shaped holes through which the beams can pass, and then fix the welded I-beams in parallel. The result of comparing the beams is very important. If two I-beams have large parallel errors, very serious tire wear will occur.

CIMC Side Wall Semi Trailer in Factory

4. Connect side beams, welding king pins

At this time, the main beam is basically formed, only the side beams are welded to form the frame structure. And the traction pin traction plate is welded to the position required in the contract, the welding process is required to be high, otherwise the triaxle with boards drop side trailer will be skewed.

5. Welding frame, welding suspension

At this time, the welding suspension must strictly control the size and maintain the squareness, otherwise it will cause tire wear.

6. Lay the bottom plate and removable wall

That is, the bottom plate and removable wall is fully welded on the frame. There is nothing to say at this step.

CIMC drop side trailer is in production

7. Frosted and painted

Frosting is the previous step of spray painting. Some manufacturers without shot blasting workshops will blow and polish the welding slag with high pressure gas at this stage.

Spray paint is usually sprayed in a well-ventilated shed. If you want to spray beautifully, you must first look at the coating and the technology of the technicians, but TITAN will spray very beautifully. Basically, you don’t have to worry about this. We will be very attentive!

8. Installation the bottom accessories and tires

After spray painting is completed, the bottom travel system is installed, and the assembled bottom is simply mounted and then precisely adjusted.

It should be noted that the tires air pressure at the factory is generally not the standard air pressure. You must confirm it again after you buy the drop side trailer.